Products

Spectral Gas Analyzer Series

High-precision Online Monitoring

Bionic Olfactory Inspection Robot Series

"Reach the Sky, Explore the Earth, Dive into the Sea, and Scale the Poles"

Oil and Gas Pipeline Health Diagnosis System

Health Diagnosis of Oil and Gas Pipelines

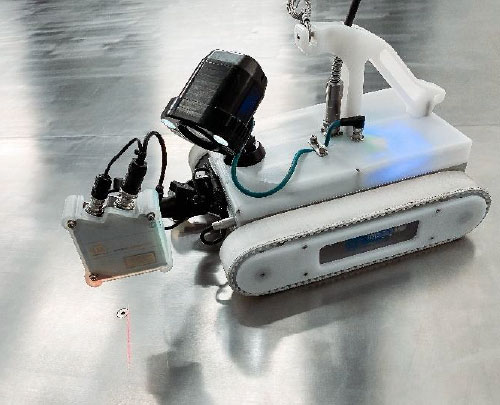

Wall-Climbing Flaw Detection Robot Series

Applications

Applications

Products of Coolight are widely applied in fields such as environmental monitoring, specialty gases for semiconductors, electric power and energy, petroleum and natural gas, aerospace, catalytic materials, agriculture, forestry, animal husbandry, and ecological research, enabling precise analysis of trace gases at the ppm, ppb, and ppt levels.

+86 150 6546 6002

+86 150 6546 6002